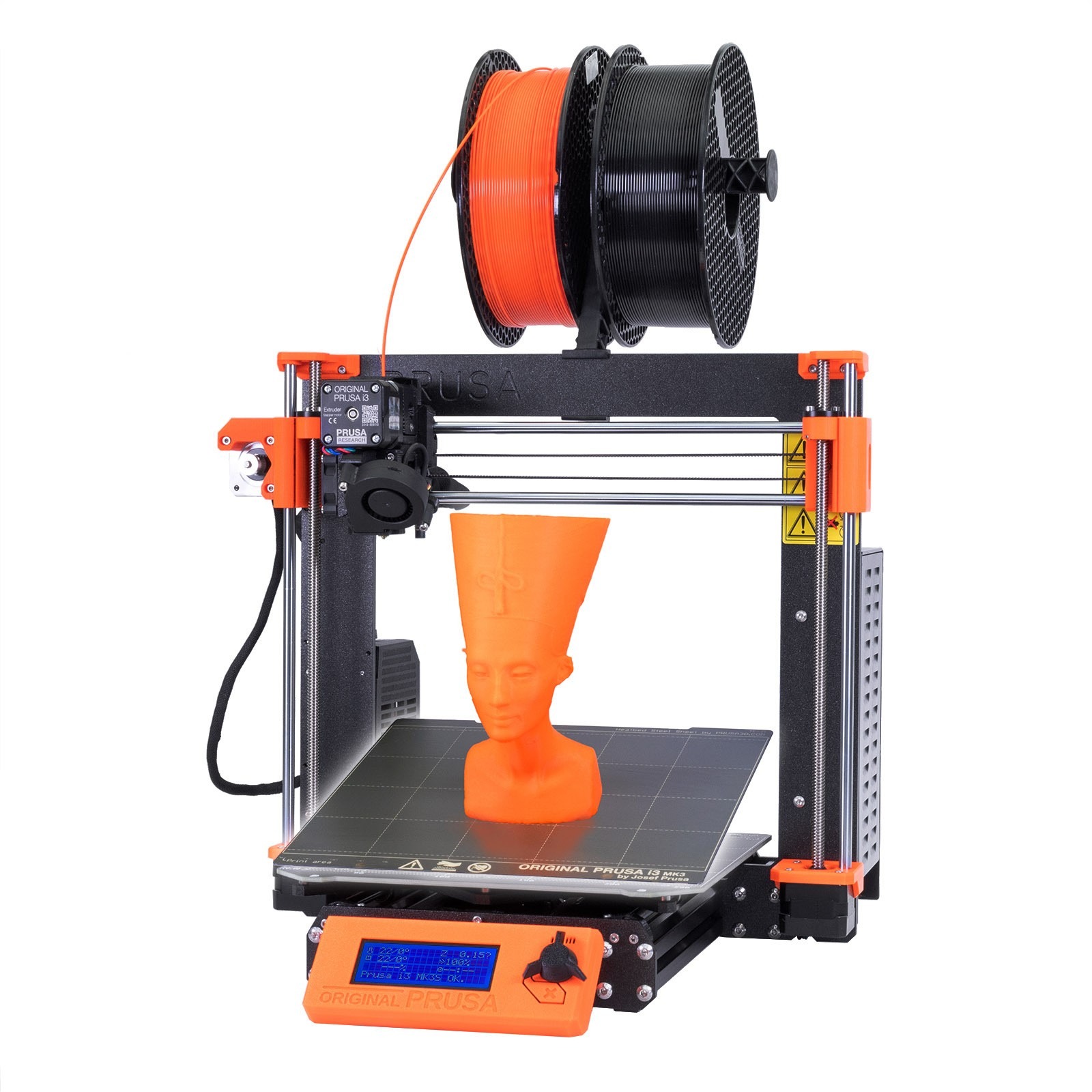

The Original Prusa i3 MK3S+ is the latest version of our award-winning 3D printers. The MK3S has been upgraded with a brand new SuperPINDA probe for improved first layer calibration, added high-quality bearings and various useful design tweaks to make the printer easier to assemble and maintain. The MK3S+ includes all the proven features of the previous models, including the heatbed with removable PEI spring steel print sheets, automatic Mesh Bed Leveling, filament sensor, power loss recovery (power panic) and safety features. And it is still as silent as ever!

The functionality of the MK3S+ can be further enhanced by unique Multi-Material Upgrade 2S for printing with up to 5 filaments simultaneously.

Main Features

SuperPinda Probe

SuperPINDA probe features a hiqh-quality sensor for a fully-automatic Mesh Bed Leveling process. Before every print, the MK3S+ probes the bed in several places and creates a virtual heightmap of the print area. This process ensures that the first layer will always be spot on!

Quality Bearings & more

The MK3S+ features a new set of metal clips for the high-quality bearings on the Y-axis. The belt tensioning mechanism on the X-axis was reworked and the X-end plastic parts reinforced. The filament path in the extruder was altered for better support of flexible filaments.

Removable Print Sheets

Spring steel sheets are easy to maintain and make removing the printed object from the print surface a breeze. We offer three types of print surface: smooth, textured and satin to cover all your needs when printing from a wide range of different materials - most of which do not require any special separation layers or surface preparation.

High-Quality Parts

The MK3S+ features an aluminum extrusion Y-axis assembly. Thanks to the milled dural frame, the MK3S+ is stable, rigid, and easy to assemble. Combined with our internally developed extruder featuring Bondtech gears and the E3D V6 hotend, the MK3S+ can print high-quality objects up to 210 mm in height.

Power Loss Recovery

Are you afraid of a blackout ruining your 48-hour print? Worry no more - the MK3S+ can deal with that! The printer can fully recover from the loss of power and continue printing exactly where it left off. It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location.

Filament Sensor

The MK3S+ further enhances the reworked extruder from the MK3S. The built-in filament sensor uses a reliable trigger system, which detects whether a strand of filament is inserted into the extruder. It can detect any type and color of filament and is not susceptible to mechanical wear.

Mesh Bed Leveling

Thanks to the SuperPINDA probe, the MK3S+ can use the Mesh Bed Leveling process to compensate for microscopic imperfections of the print sheet, and inconsistencies caused by the assembly and stacking of the manufacturing tolerances of various parts. Achieving a great-looking first layer is quick and easy.

Slice with PrusaSlicer

Our internally developed multiplatform slicer comes with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

Support for a wide range of Materials

The MK3S+ is fully compatible with a wide range of various types of materials. No matter whether you want to print something for fun from PLA and flexible materials, or you need to produce durable prototypes from PETG, ASA, Polycarbonate and Polypropylene - the MK3S+ can handle them with ease.

Open-source Hardware & Firmware

We develop firmware for all of our 3D printers and test every new version thoroughly before release. Ongoing development and regular updates ensure that our machines are packed with useful features, such as print sheet profiles, automated calibration, Mesh bed leveling, advanced diagnostics, remaining print time estimation, Octoprint support and more!

Technical Parameters

| Build Volume | 25×21×21 cm (9.84"×8.3"×8.3") |

| Layer height | 0.05 - 0.35 mm |

| Nozzle | 0.4mm default, wide range of other diameters/nozzles supported |

| Filament diameter | 1.75 mm |

| Supported materials | Wide range of thermoplastics, including PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA/BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill and other filled materials. |

| Max travel speed | 200+ mm/s |

| Max nozzle temperature | 300 °C / 572 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Extruder | Direct Drive, Bondtech gears, E3D V6 hotend |

| Print surface | Removable magnetic steel sheets(*) with different surface finishes, heatbed with cold corners compensation |

| Printer dimensions (without spool) | 7 kg, 50×55×40 cm; 19.6×21.6×15.7 in (X×Y×Z) |

| Power consumption | PLA settings: 80W / ABS settings: 120W |

Full Features List (October 2021 Edition)

- Controller: EINSY RAMBo 8-bit board with Trinamic 2130 drivers (256 microstepping), co-developed with Ultimachine, sensorless homing for X and Y axes

- Mesh Bed Leveling: Advanced high-quality SuperPINDA sensor (Super Prusa INDuction Autoleveling sensor)

- Print sheet profiles: Firmware supports print sheet profiles to store Live Z calibration data to enable quick switching between different print sheets.

- Filament sensor: IR sensor built-in, supports filament auto-loading. Print pauses when filament runs out.

- Power Panic: Hardware-based, single G-code line accuracy

- Ethernet connection: via Raspberry Pi (optional)

- Wi-Fi connection: via Raspberry Pi (optional)

- Advanced sensors: 3 thermistors, fans RPM monitoring, SuperPINDA

- Calibration: Automatic, Mesh Bed Leveling, SelfTest

- Print medium: SD card (16 GB card included)

- Firmware update: via PC (USB cable)

- PSU: Custom-made Delta PSU with hardware-based power panic

- Advanced features: Automatic filament loading, steel sheet profiles, Octoprint compatibility and more

- New features introduced through firmware upgrades

6 reasons to buy the MK3S+

We offer 24/7 tech support via live chat and email in seven languages. Our printers come with detailed instructions and guides for easy assembly and maintenance. You can also visit our knowledge base, community forum, Facebook groups and official Blog, where we publish useful 3D printing tips and tricks, contests and more!

ADVANTAGES OF AN ASSEMBLED 3D PRINTER

Compared to the assembly kit, the assembled printer differs only in the form in which you receive it. The printer comes pre-assembled and tested right out of the box. To start your first print, simply plug it in, run the initial calibration, and you are good to go. It is an ideal choice for businesses where there is a need to start printing as soon as possible.

Built-in Safety Features

Original Prusa 3D printers are well-known for their reliability and safe operation. Every part of our printers is thoroughly tested in-house. The MK3S+ is equipped with three thermistors and comes with a custom-built high-quality Delta power supply. The printer can recognize issues with heating and stop operation to prevent damage.

Open-source and Community Friendly

All parts of our printer are open-source, which means we publish all source codes and blueprints online. The community around our products is huge and the feedback is overwhelmingly positive - don't believe us? Check out Facebook groups and YouTube videos! There's so much to do with your 3D printer - buying it is just the beginning!

Ready for the Multi-Material Upgrade 2S

Multi Material Upgrade 2S is our unique add-on option for printing with up to 5 different filaments simultaneously. Multi-material could be your next step in the 3D printing world and the MK3S and MK3S+ are completely ready for the upgrade! MMU2S also allows you to print a soluble support interface - check out the video!

Upgradability

One of the most popular features of the Original Prusa i3 concept is upgradability. When you buy our 3D printer, you can upgrade it later to a newer version, so you don't need to buy a whole new model every two years like, for example, your phone or laptop. We also keep supporting our 3D printers with regular firmware updates that bring new features!

Ready to print settings

We provide high print settings with the printer, so you don't have to dive into complex new programs the second you finish the build. You can start printing right away, and this gives you a great head start!

These settings are great for all kinds of objects, not just for a couple of prepared showpieces. After a while, when you're familiar with the printer, you can, of course, dive into tinkering ;-)

We are developing our own slicing software. PrusaSlicer is a feature-rich, frequently updated tool that contains everything you need to export the perfect print files for your Original Prusa 3D printer. But of course, we also have the settings for the third party slicers like Simplify3D, Cura, etc.

MK3S+ vs MINI+ Comparison

Original Prusa i3 MK3S+ Original Prusa i3 MK3S+ |

Original Prusa MINI+ Original Prusa MINI+ |

|

| Build volume | 250 x 210 x 210 mm | 9.84 x 8.3 x 8.3 in | 180 x 180 x 180 mm | 7 x 7 x 7 in |

| Layer height | 0.05 – 0.35 mm | 0.05 – 0.25 mm with 0.4 mm nozzle |

| Max travel speed | 200+ mm/s | 200+ mm/s |

| Max hotend/heatbed temp. | 300 °C / 120 °C (572 °F / 248 °F) | 280 °C / 100 °C (536 °F / 212 °F) |

| Mainboard | Einsy RAMBo 8-bit board with Trinamic 2130 drivers co-developed with Ultimachine | Custom 32-bit Buddy electronics with STM32 and latest Trinamic 2209 silent stepper drivers |

| MMU2S support | Yes | No |

| Extruder | Direct drive | Bowden system with 3:1 gearing |

| LCD screen | Monochromatic LCD | 2.8″ graphic 65k color screen |

| Print surface | magnetic heatbed with removable PEI spring steel sheets | magnetic heatbed with removable PEI spring steel sheets |

| Filament diameter | 1.75mm | 1.75mm |

| Number of materials (simultaneously) | 1 | 1 |

| Nozzle diameter | 0.4mm (default) / other nozzle diameters supported | 0.4mm (default) / other nozzle diameters supported |

| Supported materials | Any thermoplastic including Nylon and Polycarbonate |

Most thermoplastics except Carbon filled |

| Filament sensor | Yes (IR) | Optional upgrade |

| Power panic | Hardware-based, single G-code line accuracy | Future software upgrade, single layer accuracy |

| Ethernet connection | Via Raspberry Pi | Yes |

| Wi-Fi connection | Via Raspberry Pi | Separate future upgrade (ESP Wi-Fi module) |

| Advanced sensors | 3 thermistors + SuperPINDA, fan RPM sensors | 3 thermistors + SuperPINDA, fan RPM sensors |

| Farm mode | No | Yes (upcoming feature) |

| Calibration | Automatic, Mesh Bed Leveling | Automatic, Mesh Bed Leveling |

| Print medium | SD card | USB drive / LAN |

| Firmware update interface | USB port | USB drive / LAN |

| Power supply | 240W, custom made by Delta with Power Panic HW | 160W, external adapter by Mean Well or Delta depending on the region |