Description:

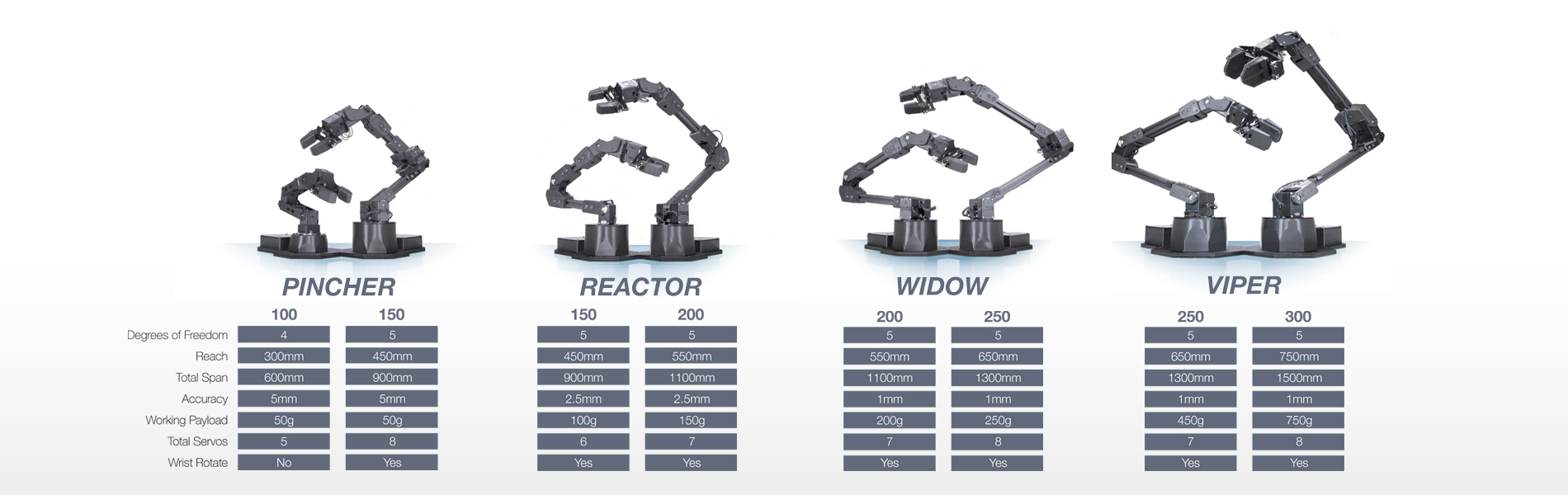

WidowX 250 robotic arm: 6 DOF, 1m30 wingspan

The 6-axis WidowX 250 robotic arm offers a total wingspan of 1m36 for a reach of 68 cm. It ensures a payload of 250 g, and a precision of movement to the nearest millimeter.

This programmable robotic arm is controlled by Dynamixel U2D2 and CM9.04 and guarantees great flexibility in use and design. Its mobile rotating base and rotating wrist lay the foundations for its agility. In addition, its gripper with interchangeable fingers allows you to test design and 3D printing. Additional foam and rubber has been slipped into the box.

9 Dynamixel servomotors for a 100% programmable and ultra-precise arm.

If this robotic arm amazes us with its high precision of movement, it is because it is equipped with 9 Dynamixel servomotors from the XM and XL series. These latest-generation servos designed by Robotis feature high-performance torque, a solid and intelligent design, and above all, extensive programming possibilities according to your needs.

The high resolution of these servomotors allows this flexibility of movement that you will appreciate when using your mobile arm, project after project.

Technical specifications of the WidowX 250 6-axis Robotic Arm

- Degrees of freedom: 6

- Range: 680 mm

- Total span: 1360 mm

- Accuracy: 1 mm

- Useful load: 250 g

- Total number of servomotors: 9

- Rotating wrist: yes

Included:

- 7 XM430-W350-T servomotors

- 2 XL430-W250-T servomotors

- 1 Dynamixel U2D2 controller

- 1 CM9.04c controller

- 1 12 V 10 A power supply

- 1 micro USB2 cable

- WidowX 250 parts and equipment

- Extra foam and rubber for the gripper

- Drivers and additional hardware

- Mounting material for the base